Our Commitment to Quality

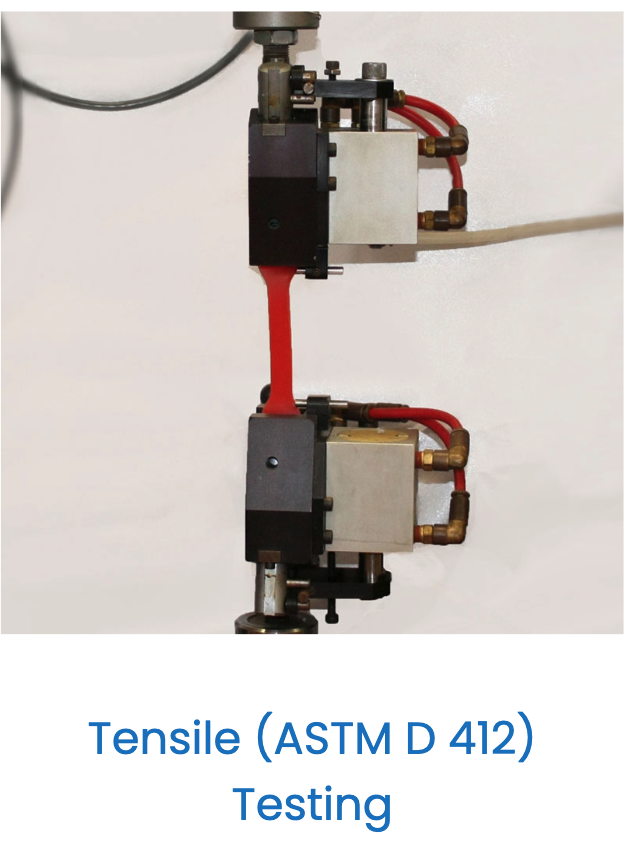

At VGS, we are committed to providing high-quality products that meet or exceed customer expectations. To ensure the highest standards, we subject all our materials to rigorous testing by independent labs.

Our manufacturing process includes precise measurement with calipers and CMM (Coordinate Measuring Machines) to ensure that billets are accurate and within specification.

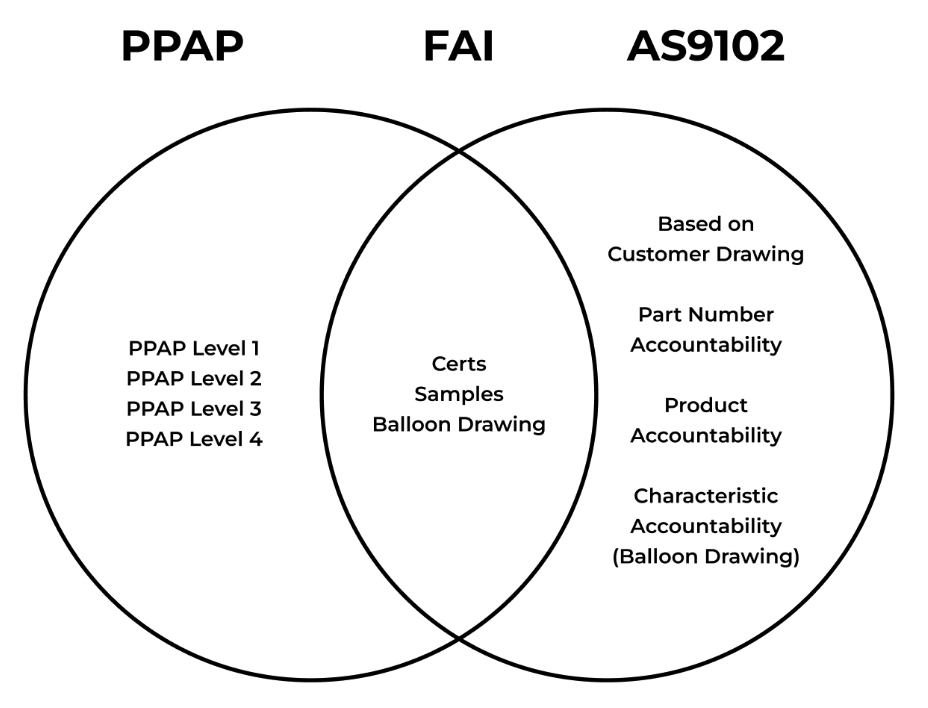

We also offer PPAP (Production Part Approval Process) and FAI (First Article Inspection) documentation upon customer request, ensuring transparency and reliability in our processes.